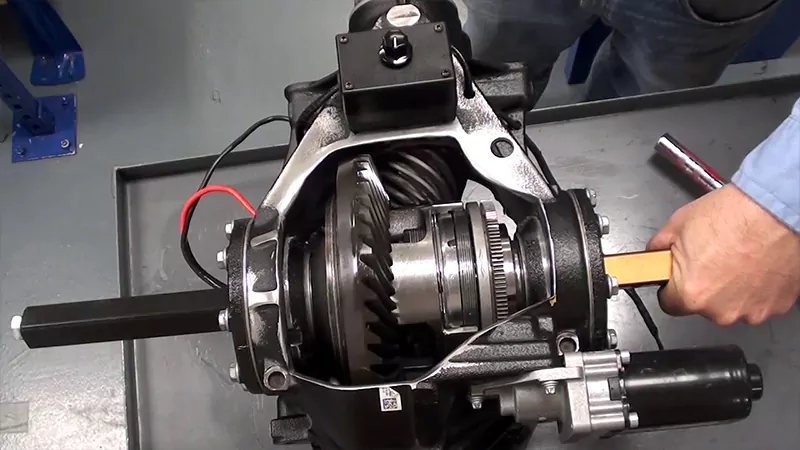

The Crown Wheel Pinion comprises two crucial elements: the crown wheel (a large circular gear) and the pinion (a smaller gear). Together, they form a fundamental part of a vehicle’s differential system.

Role in Differential Mechanism

The crown wheel and pinion enable the distribution of power from the vehicle’s engine to its wheels. They play a pivotal role in the differential mechanism, allowing for smooth turning and movement.

Importance of a Well-Crafted Crown Wheel Pinion

A well-crafted crown wheel pinion ensures the efficient transmission of power from the engine to the wheels. The right design and precision manufacturing directly impact a vehicle’s performance, stability, and fuel efficiency.

Factors Influencing Crown Wheel Pinion Performance

Several factors influence the performance of a crown wheel pinion, including gear ratio, tooth shape, material selection, and manufacturing precision. Each of these elements contributes to the overall efficiency and reliability of the mechanism.

Gear Ratio

The gear ratio between the crown wheel and pinion defines the torque and speed relationship, impacting the vehicle’s acceleration and top speed.

Tooth Shape

The design and shape of the teeth on the crown wheel and pinion affect the smoothness of gear engagement, minimizing noise and ensuring a seamless driving experience.

Conclusion

The Crown Wheel Pinion, a seemingly small but crucial component in a vehicle’s differential mechanism, significantly impacts the overall performance and efficiency. Understanding its role and optimizing its design and manufacturing process can lead to more efficient and reliable automobiles.