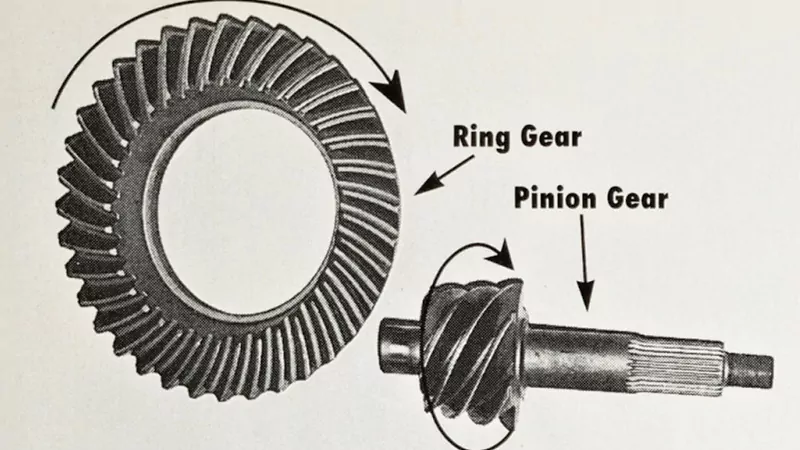

Achieving the correct pattern for a ring and pinion gear set is essential for ensuring optimal performance and durability of the differential. This process involves meticulous alignment to guarantee smooth operation, minimize noise, and reduce wear over time. Here’s a comprehensive guide on how to achieve and verify the correct gear pattern.

Initial Setup

Achieving the correct pattern for a ring and pinion gear set is essential for ensuring optimal performance and durability of the differential. This process involves meticulous alignment to guarantee smooth operation, minimize noise, and reduce wear over time. Here’s a comprehensive guide on how to achieve and verify the correct gear pattern.

Adjusting Backlash

Backlash, the amount of play between the ring and pinion gears, is critical for proper gear engagement. Adjust the backlash by moving the differential carrier side to side using shims or adjusters. Refer to the manufacturer’s guidelines for the recommended backlash range, typically between 0.005 to 0.009 inches (0.13 to 0.23 mm).

Checking the Pattern

Apply a thin layer of gear marking compound to several teeth on the ring gear. Rotate the ring gear back and forth to transfer the compound pattern onto the pinion gear teeth. Carefully observe and analyze the contact pattern formed on the ring gear teeth.

- Drive Side: This is the convex side of the ring gear teeth that engage when the vehicle is moving forward.

- Coast Side: This refers to the concave side of the ring gear teeth, engaged during coasting or reverse motion.

Interpreting the Pattern

A well-centered pattern on both the drive and coast sides of the ring gear teeth indicates proper contact and load distribution. Understanding the pattern helps diagnose the pinion depth:

- Pinion Too Deep: If the pattern is near the top (heel) of the ring gear teeth, the pinion depth is excessive. Adjust by adding shims to reduce the depth.

- Pinion Too Shallow: Conversely, if the pattern is near the bottom (toe) of the ring gear teeth, the pinion depth is insufficient. Adjust by removing shims to increase the depth.

Making Adjustments

Based on the pattern analysis, adjust the pinion depth accordingly by adding or removing shims. Recheck the backlash after each adjustment and readjust if necessary to ensure it falls within the specified range. Reapply gear marking compound and verify the pattern until the correct alignment is achieved.

Final Verification

Once the correct pattern is obtained, re-torque all fasteners to the manufacturer’s specifications to secure the assembly. Double-check the backlash to ensure it remains within the recommended range. Verify the gear oil level is correct and perform a road test to confirm quiet and smooth operation under load.

Conclusion

Achieving the correct pattern for ring and pinion gears requires precision and attention to detail. Proper setup not only enhances performance by ensuring efficient power transfer and reduced wear but also contributes to a quieter and more reliable drivetrain. For those unfamiliar with differential setup, seeking assistance from a qualified mechanic or technician is advisable to ensure optimal results. Mastering this process is key to maximizing the performance and longevity of your vehicle’s drivetrain components.